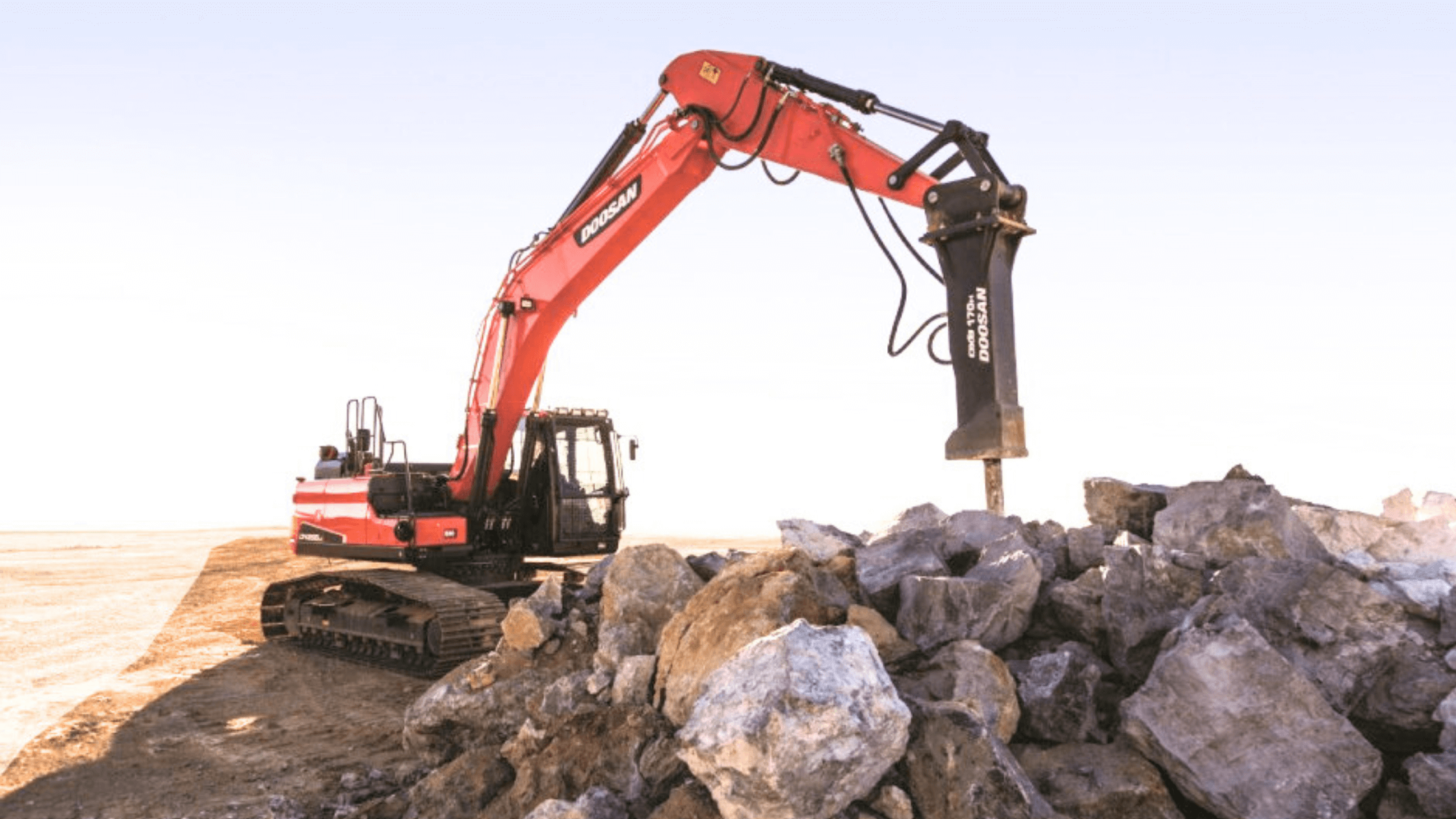

Hydraulic rock breakers, commonly referred to as hydraulic hammers, have revolutionized the demolition and excavation industries. In a variety of industries, including quarrying, demolition, and mining, these strong instruments have become essential.

We'll talk about the significance of hydraulic rock breakers and how they've changed the way we handle difficult assignments in this blog post.

Enhanced production and Efficiency:

One of the main factors contributing to hydraulic rock breakers' high value is their capacity to increase production and efficiency. These breakers can easily cut through resistant materials like boulders, concrete, and asphalt thanks to their tremendous force and accuracy. Hydraulic rock breakers greatly minimize the time and effort needed for excavation and demolition jobs when compared to conventional techniques like physical labour or explosives.

Versatility and Adaptability:

Hydraulic rock breakers can be found in a variety of sizes and configurations, which makes them incredibly versatile and adaptable to different job requirements. These breakers are easily placed to many pieces of equipment, including excavators, backhoes, and skid steers, and can be used for a variety of tasks, including demolishing concrete buildings, trench excavation, and breaking massive rocks in quarries.

Precision and Control:

The accuracy and control of hydraulic rock crushers during use is a significant additional benefit. Hydraulic breakers enable users to precisely target the targeted location for breaking, unlike traditional demolition techniques that frequently cause collateral damage.

Safety and operator comfort:

When doing any construction or demolition operation, safety comes first. By lowering the risks involved with manual labor-intensive procedures or explosive tactics, hydraulic rock breakers help to create safer working environments. Hydraulic breakers reduce the possibility of operator fatigue and musculoskeletal injuries by removing the need for physical exertion.

Environmental Considerations:

When compared to conventional demolition techniques, hydraulic rock breakers are also more environmentally friendly. These breakers lessen air and water pollution by avoiding the use of explosives or chemicals. Additionally, their controlled cracking and accuracy reduce the trash produced during demolition, allowing for greater material recycling and reuse.

Summary

It is impossible to exaggerate the value of hydraulic rock crushers in the demolition and excavation industries. The way heavy-duty activities are completed has changed as a result of their improved efficiency, adaptability, precision, and safety features. Hydraulic rock breakers have grown to be a useful tool in a variety of industries thanks to their capacity to boost productivity, cut costs, and minimise environmental effects.