In the vast realm of industrial tooling, a particular set of devices stand out due to their remarkable features and benefits - needle scaler air tools. These tools have revolutionized surface preparation techniques across various industries. But why are needle scaler air tools so essential? Let’s explore

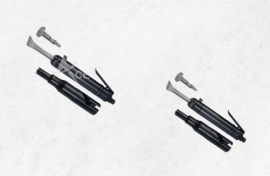

Firstly, needle scaler air tools offer unparalleled efficiency. Surface preparation is a critical process that involves removing corrosion, paint, or scale from various materials. Traditional hand tools can be tremendously time-consuming and are often unable to reach small crevices and uneven surfaces. However, needle scaler air tools can do this job faster and better. With their compact design housing multiple needles, they tap into the power of pneumatics to effectively chip away rust, scale or old paint, even in hard-to-reach areas.

Secondly, needle scaler air tools are incredibly versatile. Their impressive functionality is not limited to just metal surfaces but also excels on concrete and stone. Whether you're preparing a metal surface for a fresh paint job, eradicating rust from industrial equipment, or chipping away old plaster from a brick wall, a needle scaler air tool is your go-to device.

The third reason lies in the durability and robustness of needle scaler air tools. Made from high quality, industrial-grade materials, they are designed to endure harsh conditions and perform reliably over a long period of time. This resilience reduces the frequency and costs of tool replacements, ensuring increased productivity and cost-effectiveness.

Fourthly, the increasing focus on worker safety underscores the importance of needle scaler air tools. Traditional surface preparation methods can put workers at risk of repetitive strain injuries due to the manual labor involved. Conversely, needle scaler air tools significantly diminish this risk, providing a safer and more ergonomic solution.

Additionally, the maintenance of needle scaler air tools is a breeze. With simpler mechanisms and fewer moving components than most power tools, the requirement for regular maintenance is low. This allows for longer work periods without disruption, enhancing work efficiency and productivity. Lastly, advancements in technology have provided needle scaler air tools with better features such as adjustable power settings, interchangeable needle sets, and vibration reduction handles. These enhancements have enabled more precise and comfortable usage, further elevating the indispensability of these tools in surface preparation tasks.

In conclusion, needle scaler air tools are a game-changer when it comes to surface preparation. Their efficiency, versatility, durability, safety features, ease of maintenance, and technological upgrades make them an essential tool in every workshop. It's clear that in the world of surface preparation, the needle scaler air tool remains unrivaled.